Fabrication of Litz Bundles with Nanowires for High-Frequency Applications

Collaborators: Peter H. Lewis, Ernest S. Kim, Kasey J. Russell, Amy Duwel, David J. Carter

Patent Application: Wire Fabricator

Conductive wires that transmit alternating current (AC) at high frequencies suffer from the skin effect. As the AC frequency increases, the current going through the wire gets pushed toward the surface of the wire due to the changing magnetic field from the alternating current. The core of the wire no longer conducts electricity as a result of this effect, leading to wasted material and poor conductivity.

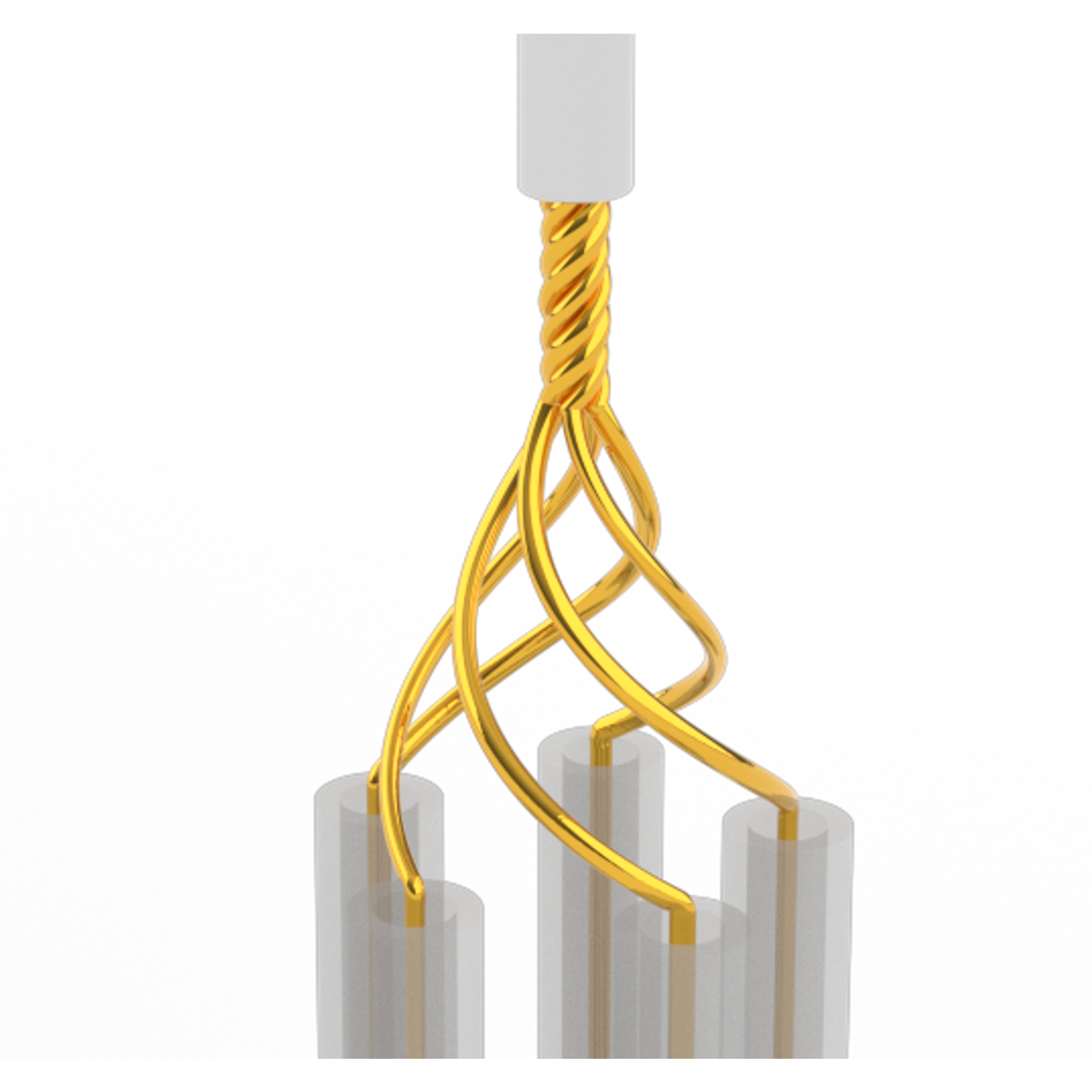

One way of circumventing the skin effect is to use bundles of stranded wires, which are known as Litz bundles. Each wire is small enough so that current flows through the entire wire diameter, while the arrangment of the Litz bundle ensures that the each wire does not hinder the performance of the other wires. Standard Litz bundles can carry AC currents up to 6 MHz without skin effect losses. For frequencies in the GHz range, strands with nanometer-range diamters are required. However, handling nanowires is infeasible using conventional wire fabrication methods.

In this project, I worked with a team to develop a method to handle and twist nanowires into Litz bundles. This method hydrodynamically holds the nanowires in place by placing each wire in a tube with flowing water. The drag of the water current provides enough force to tension the nanowires without snapping them. The head of each nanowire is attached to a thin, magnetic foil. Using a magnet, we can then pick up the tensioned nanowires and begin the twisting process. Using this method, we were able to produce Litz bundles from wires <100 nm in diameter. Although we eventually abandoned it due to shifting organizational goals, we submitted a patent for this hydrodynamic wire fabrication method.