Jitterbug: A Hybrid Digital Fabrication Platform for Rapid Prototyping of Printed Electronics

Authors: Vinh Q. Nguyen, Anika E. Harding, Kaito Yan, Nadya Peek, Corie L. Cobb

ASME IDETC-CIE 2025 Conference Proceedings, In Press.

Github

Abstract

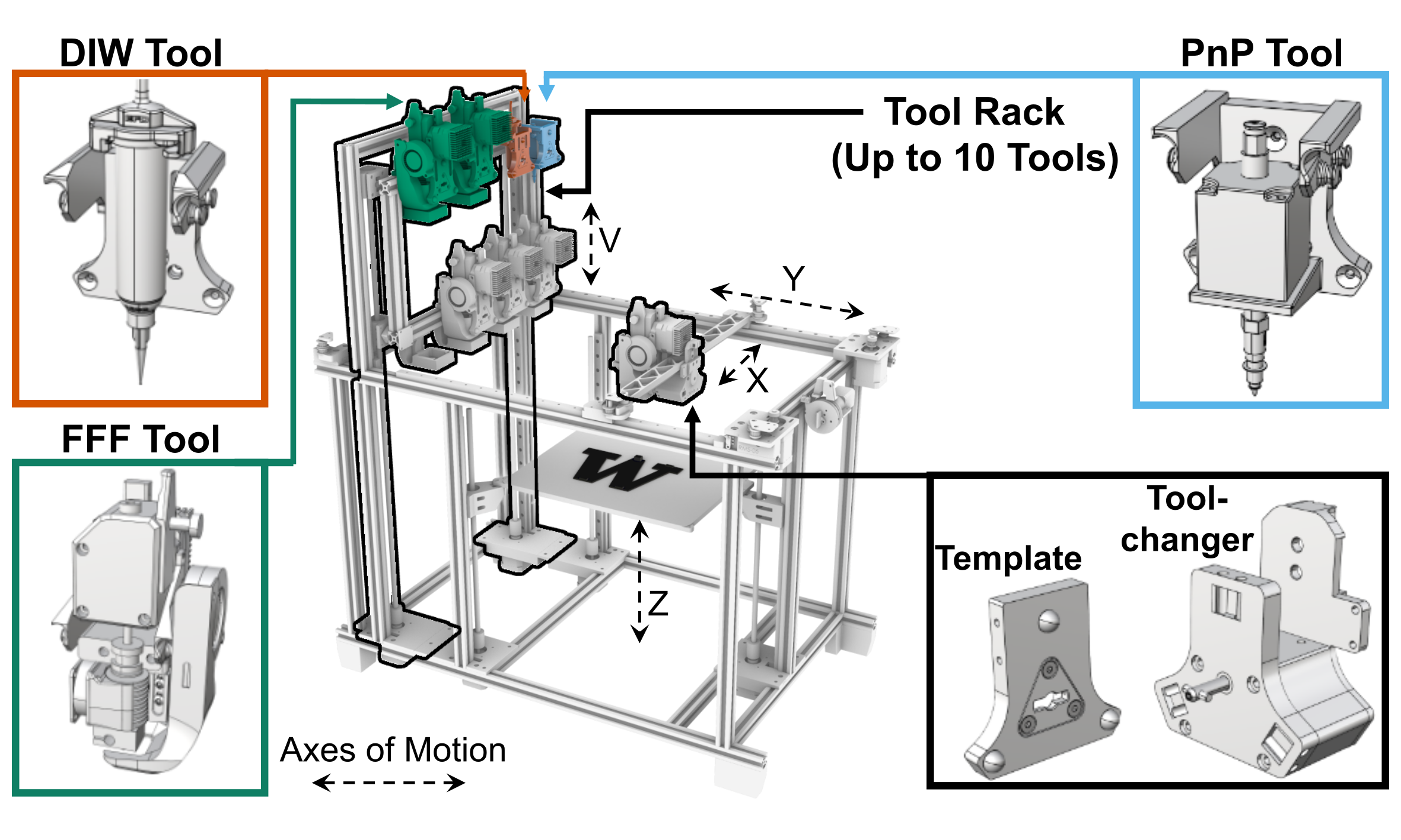

Hybrid digital fabrication combines 3D printing with additional fabrication functionality such as pick-and-place (PnP) to enable customizable, printed electronic (PE) devices with an expansive array of form factors. Researchers have investigated a wide range of new materials, methods, and processes to advance PE devices. However, existing platforms cannot be easily modified or customized, severely limiting one’s ability to adapt hybrid digital fabrication platforms to ever evolving research and prototype needs. This paper introduces Jitterbug, a hybrid digital fabrication platform that supports rapid prototyping of PEs. Jitterbug consists of a toolpath generation workflow and an automatic tool-changing hardware system that builds upon existing open-source 3-axis motion frameworks. The toolpath generation workflow allows users to design PEs and generate toolpath programs directly in its computer-aided design (CAD) environment, provides granular control of the fabrication workflow, and enables printing of conductive traces on substrates with curved features at low-incline angles (< 50°). For demonstration purposes, Jitterbug's initial tool-changing system is designed with the core fused filament fabrication (FFF), direct ink writing (DIW), and PnP tools necessary for hybrid digital fabrication; the system can support up to ten tools for different PE workflows. Jitterbug’s capabilities are demonstrated through fabrication of two functional light-emitting diode (LED) prototype devices, and its implications on designing specialized workflows for PEs are discussed.