Additive Manufacturing of Batteries with Three-Dimensional Architectures

In Progress.

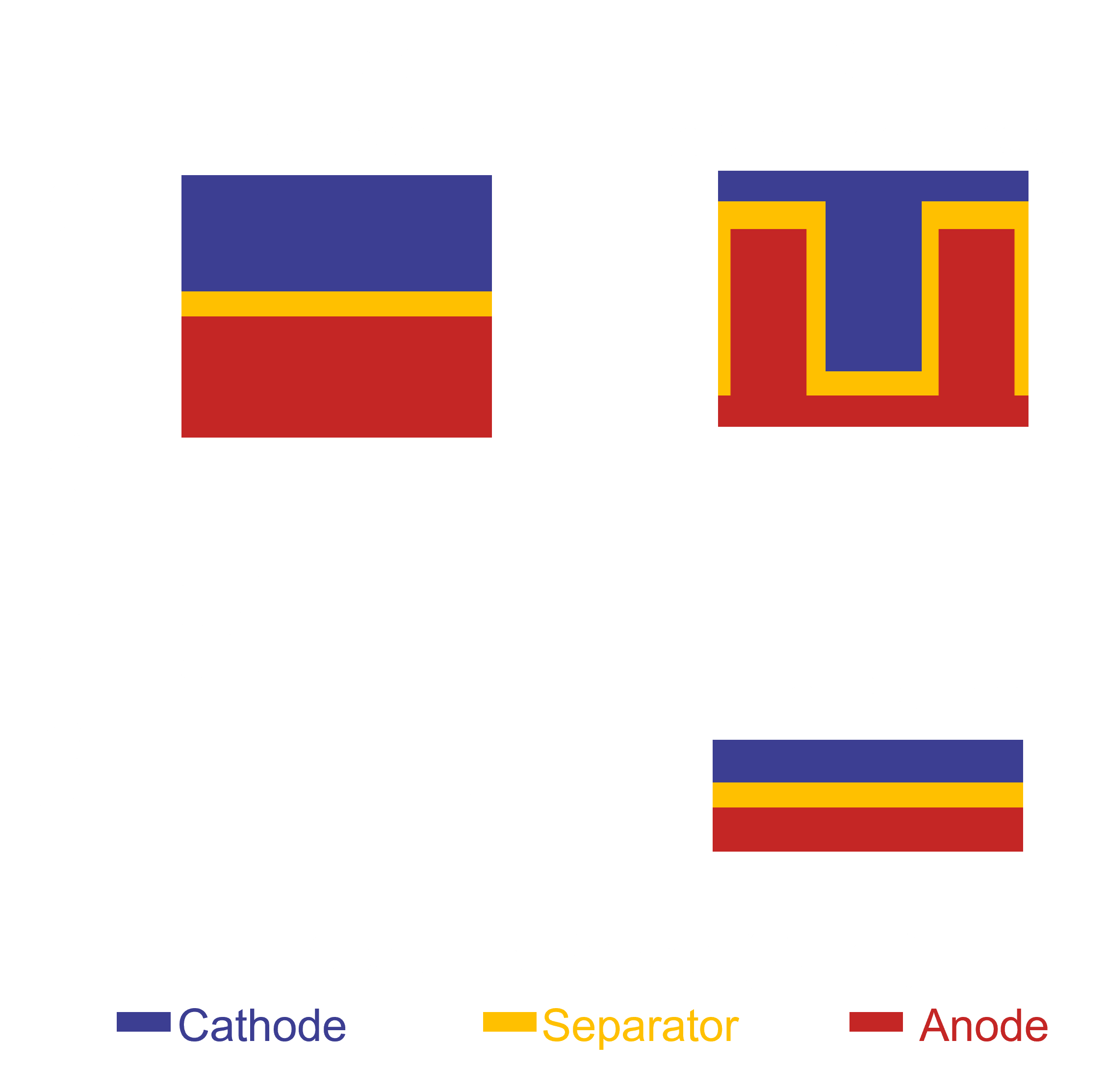

Conventional lithium-ion batteries are manufactured by slot-die or spray coating electrode slurries onto metallic current collector foils. These coated foils are then rolled up along with an electrically-insulating, ionically-conductive separator and packaged into cylindrical, prismatic, or pouch cells. Due to this manufacturing process, electrodes are planary. Therefore, the primary method of controlling an electrode's geometry is to control its coating thickness. However, this introduces a performance tradeoff known as the energy-power tradeoff.

The energy-power tradeoff is driven by the fact that electrodes are basically a maze of solid particles that ions must travel through to reach the other electrode. This maze is known as tortuosity. Thick electrodes have more active material, which allows them to store more ions and increase their total energy. However, thick electrodes have long, complex mazes (high tortuosity) that lower the power and charging speed of the battery. On the flip side, thin electrodes have low tortuosity, making them suitable for high-power applications. However, thin electrodes don't have as much active material, which lowers their total energy.

To combat this energy-power tradeoff, researchers have explored 3D battery architectures. These 3D architectures break away from conventional planar geometries and can increase the total amount of active material in electrodes while keeping the distance and tortuosity between electrodes low. This makes it possible to have both high-power and high-energy at the same time. While most research into 3D battery architectures have been fabricated through lithography and microfabrication techniques used in semiconductor processes, I am looking into how 3D printing can create more versatile, easily fabricated 3D structures. This work can potentially open up new avenues to create customizable, high-performance batteries that break away from the energy-power tradeoff and also inform manufacturing strategies that can make 3D batteries scalable.